Application

14 May 2021

Why Do We Need Tool Control Foam?

Tool control is crucial for operational efficiency in manufacturing and maintenance environments. When tools are not controlled and managed well, it can lead to issues with productivity, health and safety problems, loss of time and money, and even a negative impact on your business’s reputation. Tool control solutions are available to help mitigate these issues…

Productivity slows down

A missing tool can cause a dip in productivity for several reasons. As workers need to look for the tool, they are not getting their real work completed. Production or other work might need to be stopped or delayed until the tool is found, meaning that valuable time is lost. If one or more people or processes need to stop work, it could have a knock-on effect and mean that other tasks can’t go ahead either.

A replacement tool needs to be foundIf a missing tool can’t be found immediately, a replacement tool might need to be found to take its place. This also takes up extra time, as the tool will need to be sought and put into use. Additionally, it might not always be possible to find an exact like-for-like replacement for the missing tool. This could mean that there is no similar tool that can be used, so the job cannot be completed until the missing tool is found or a replacement is sourced. Another possibility is that the tool is replaced with another that is not fit for purpose, which could reduce productivity or even lead to a greater risk of injury, damage to equipment, mistakes, and more.

Money is lostA missing tool could cause a monetary loss to the business. If the tool cannot be found, a replacement might need to be bought or hired. This will often cost more than simply how much the tool itself costs, as someone will have to source the new tool and arrange for its delivery or collection. If the tool has found its way into machinery or products being produced, it could damage expensive machinery or product might need to be recalled, leading to further monetary loss.

The business could also lose money through taking a hit to their reputation. If the business is seen as being careless, accidents occur, or the company has to recall a product, it could mean that customers lose trust in the company. This could lead to a loss in sales, which might be difficult to recover from. A further monetary risk is one arising from potential accidents, which could lead to legal proceedings.

Increased health and safety risksCertain health and safety risks could become a problem if a tool goes missing. When you don’t know where a tool is, it could have found its way into machinery or perhaps into the product being manufactured. These situations could create performance issues and potentially increase the risk of accidents. If a tool is replaced by one that is not adequate for getting the job done, this could also mean there is a greater risk of accidents or injuries occurring. Any accident has the potential to result in a range of other problems, from lawsuits to loss of reputation.

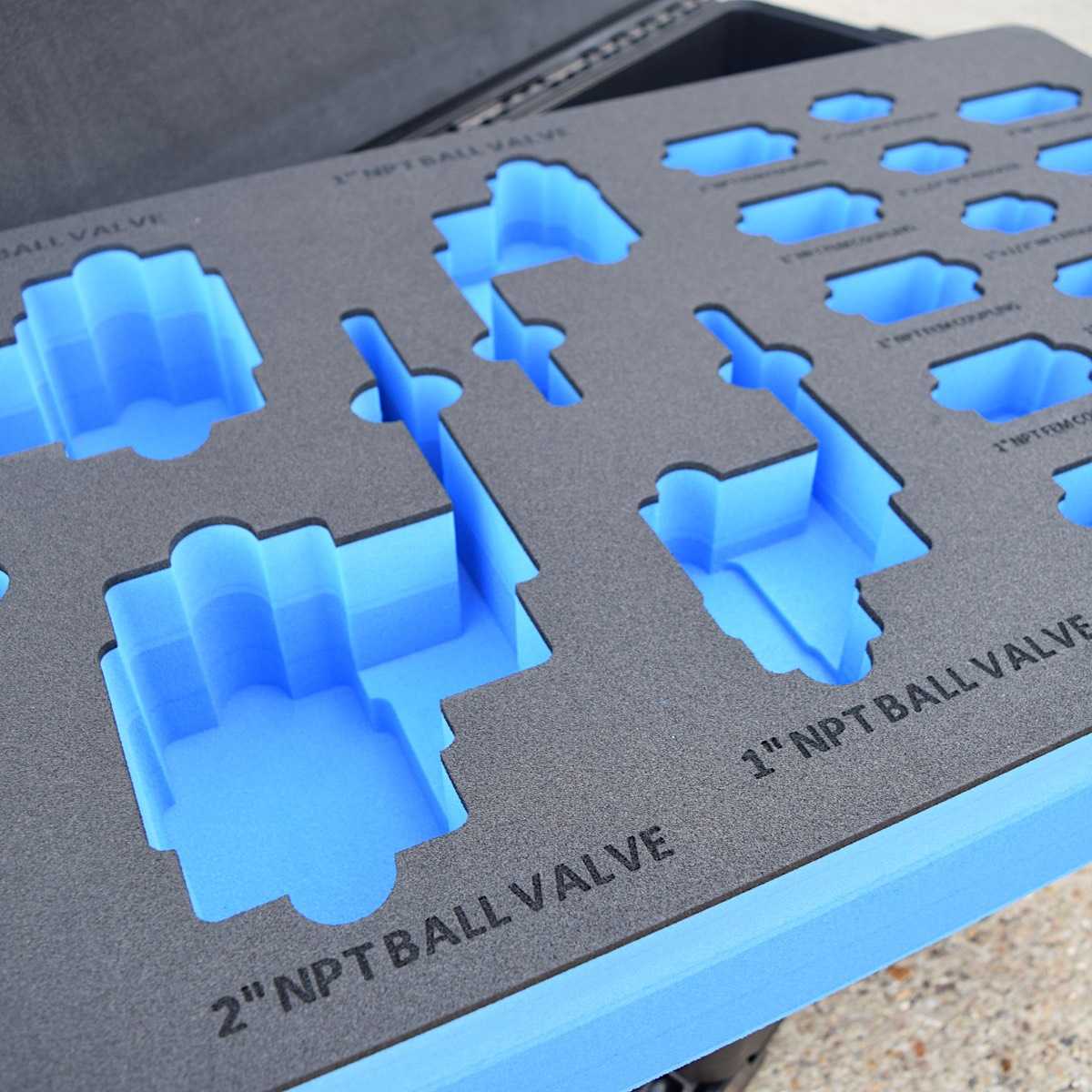

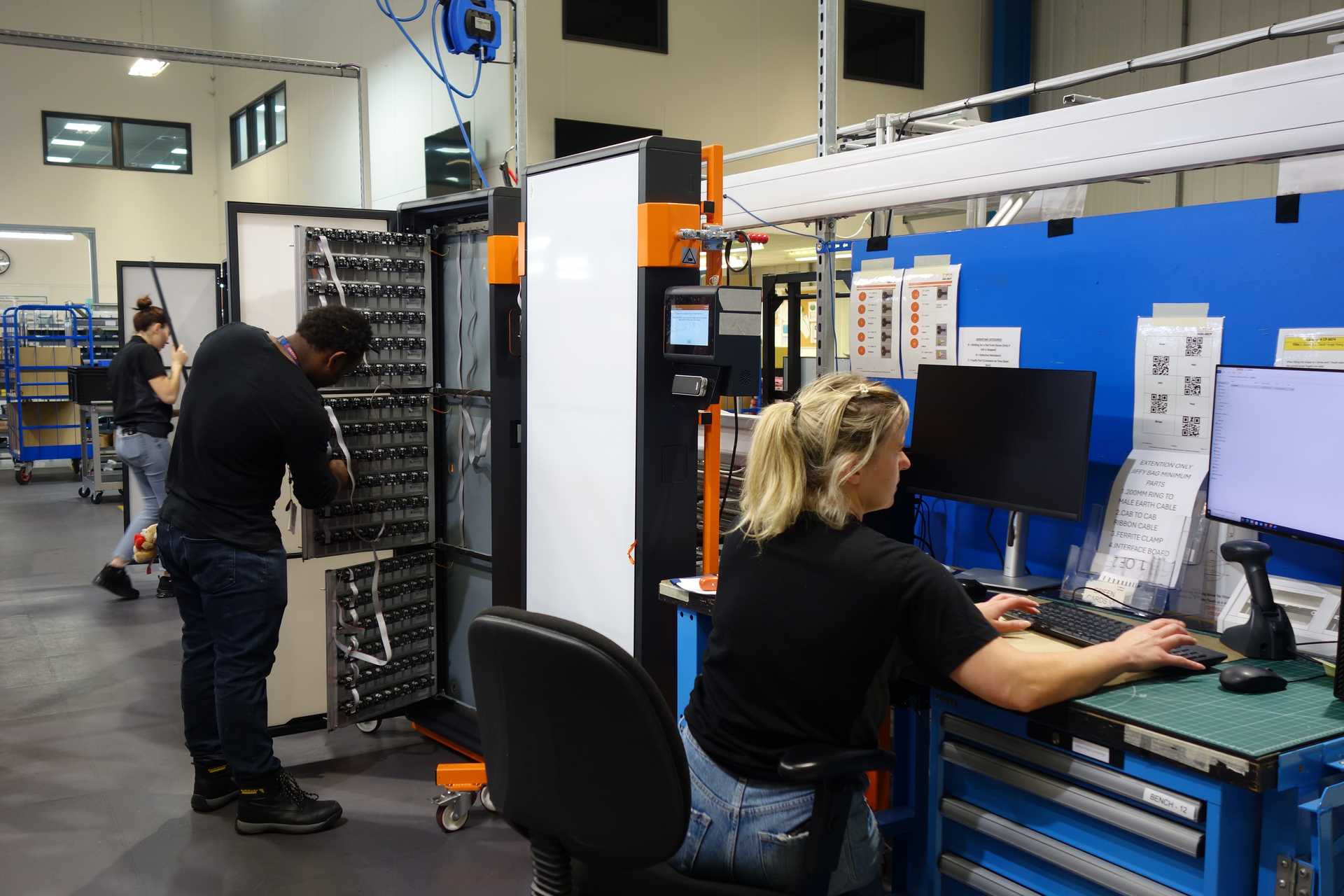

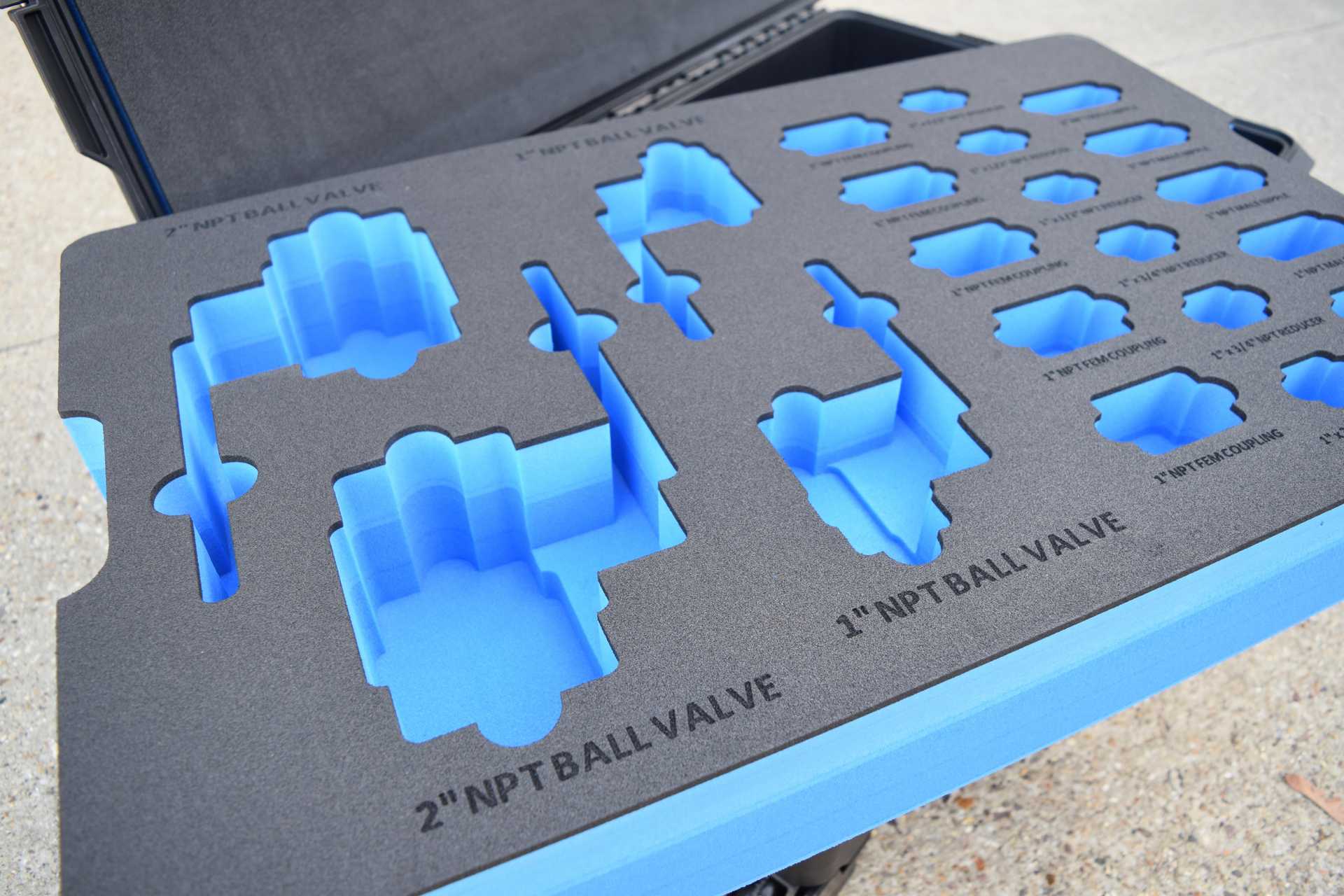

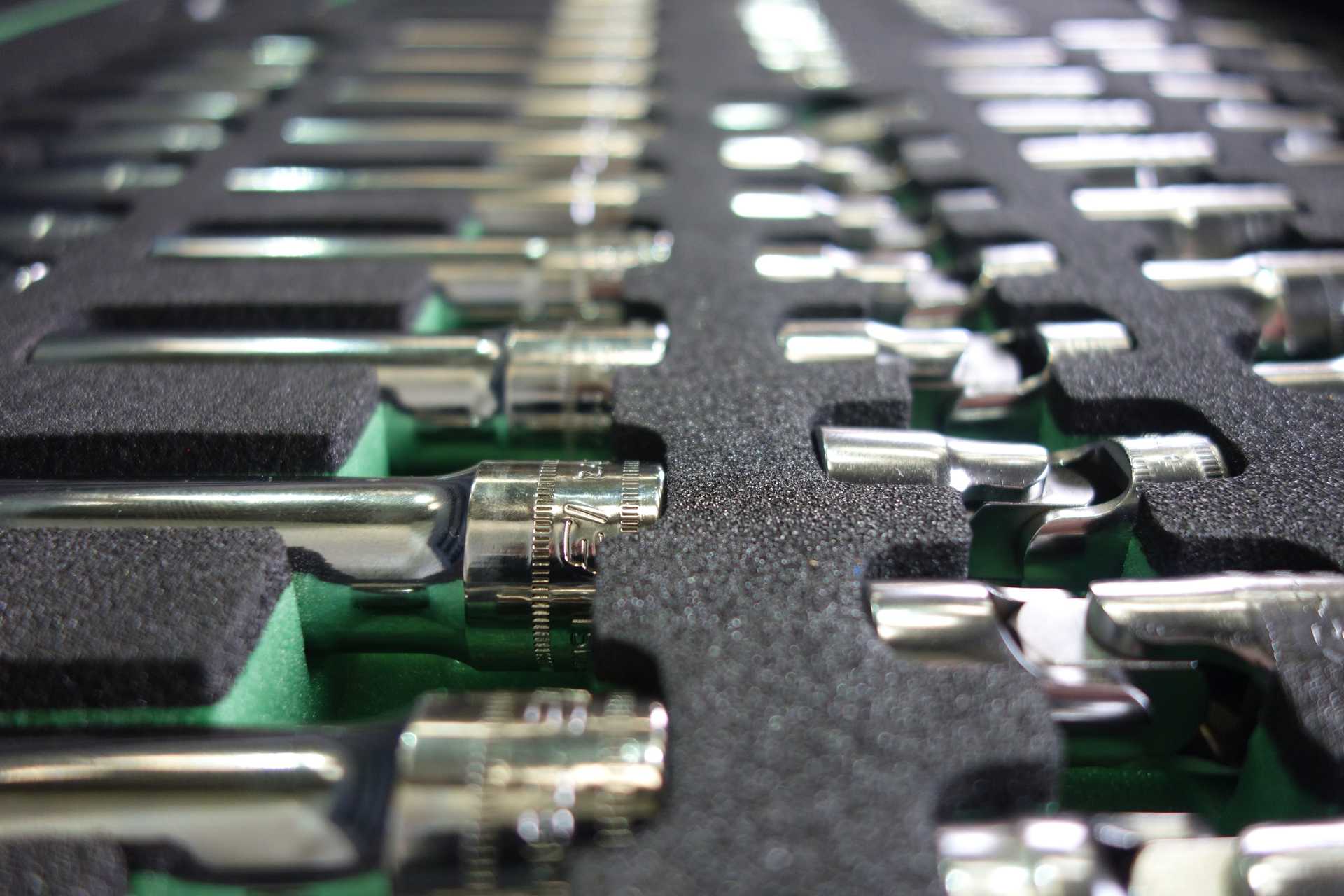

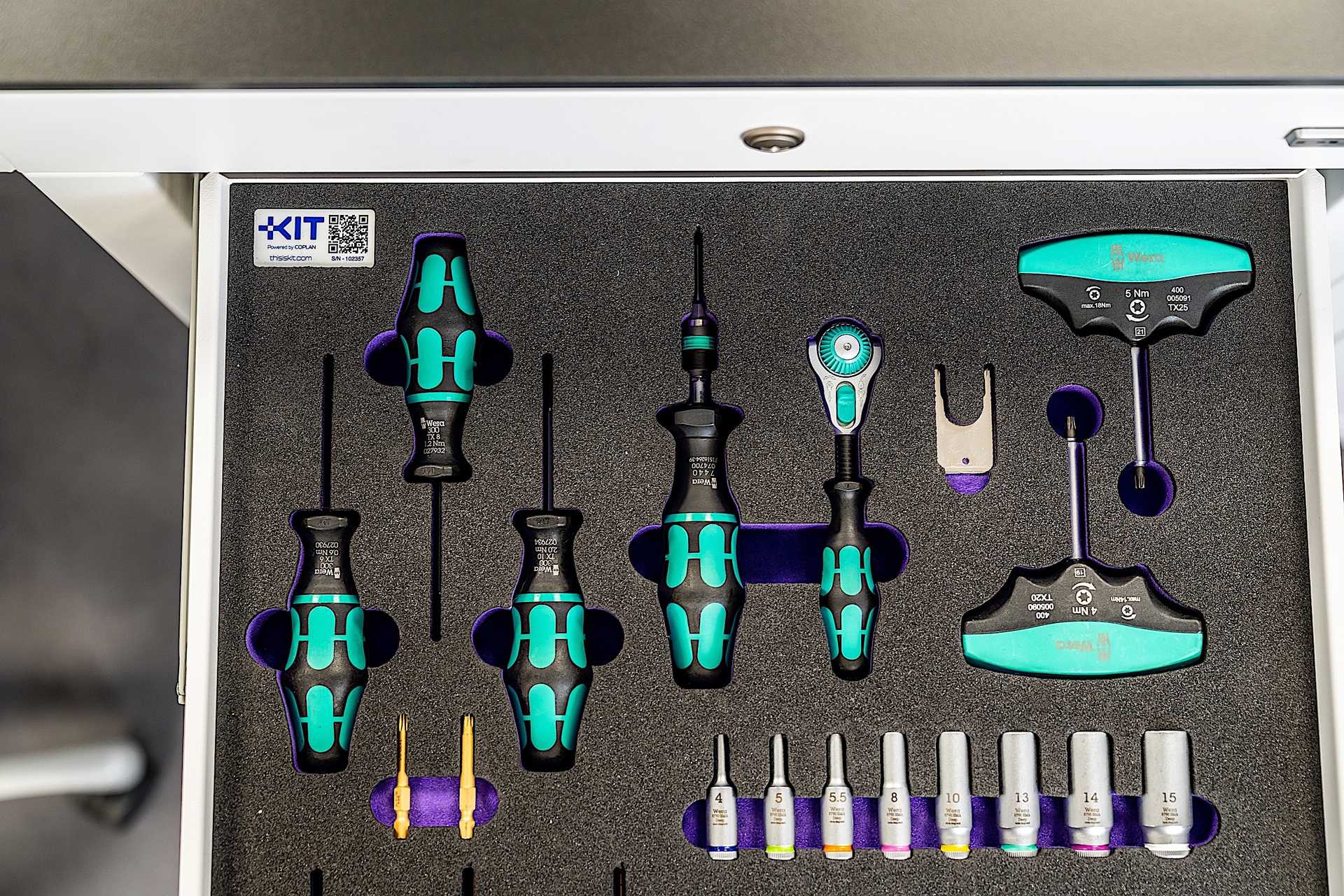

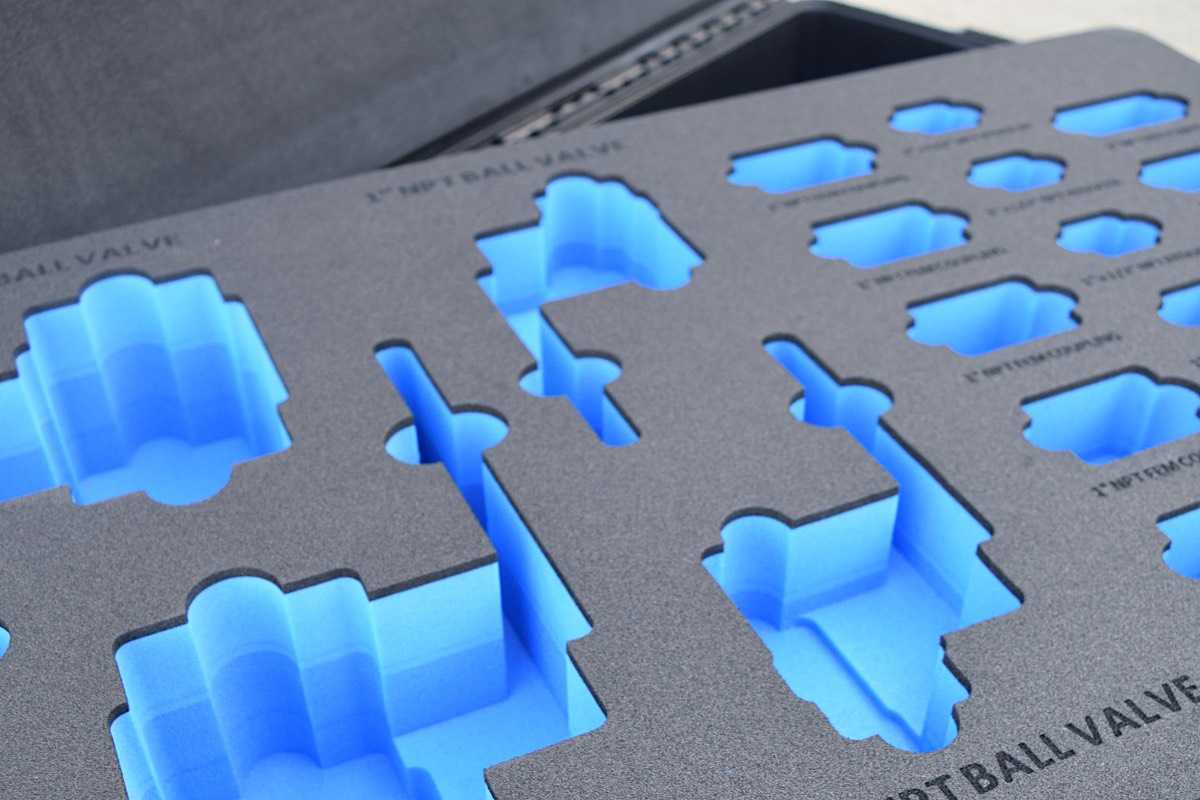

Manage Tools with Tool ControlCoplan provides a full range of solutions to help organisations keep control over their tools. Our solutions are designed to ensure that your equipment is protected and safely housed, as well as to provide visual confirmation of whether a tool has been returned or not. We offer tool control foam solutions, including tool cabinets, tool cases, foam shadow boards, and tool bags. These products are cut to your requirements and provide clear visual indicators of whether a tool is within its housing or has been removed. In addition to this, we also provide tool access control and auditing solutions to ensure all tools are audited and traced.

Coplan has been delivering tool control solutions for more than three decades. We help to protect more than £40 billion of tools and assets across our clients. We hold an ISO 9001 accreditation, which demonstrates our commitment to delivering quality products and services, and continually improving what we do. With our tool control solutions, we aim to help our customers do the same, allowing them to achieve high levels of quality and continual improvement too.

Want to know more?

If you would like to discuss a project with us, we would be delighted to receive your call.

Call us today on 01908 307 956 or alternatively please contact us.