Blog

1 June 2022

Best Practice Tips: effective tool control

If you are looking for effective tool control tips, you have come to the right place.

Tool control is essential in business. If you are not effectively controlling your tools, this could be dangerous for anyone involved. It is a part of business that must be taken seriously at all times, and that’s why we have written this article. Down below, we’re going to be looking at some of the best practice tips when it comes to effective tool control, so keep reading to find out more.

Tool Identification MeasuresMarking tools is the most common method of identifying them. Traditionally, the person would mark their tools with their name, their initial, or another identifying mark that allows them to be sure that the tool belongs to them. If someone knows that their tool can be traced back to them, they are more likely to report it missing in the first place rather than buying a replacement and hoping nobody notices. It also ensures that the owner will get their tool back a lot faster as the marking will stand out. This will change the behaviour of your team completely.

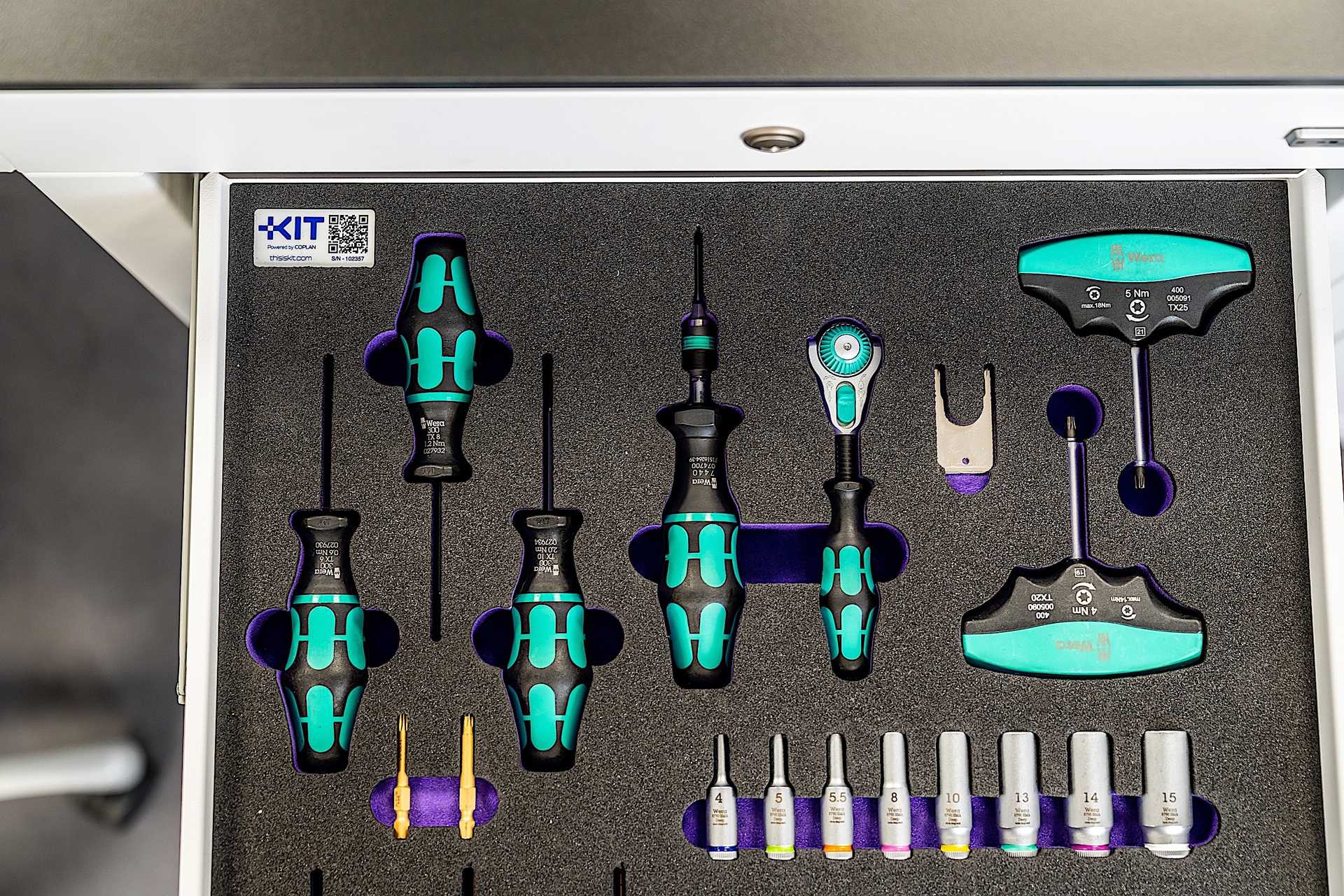

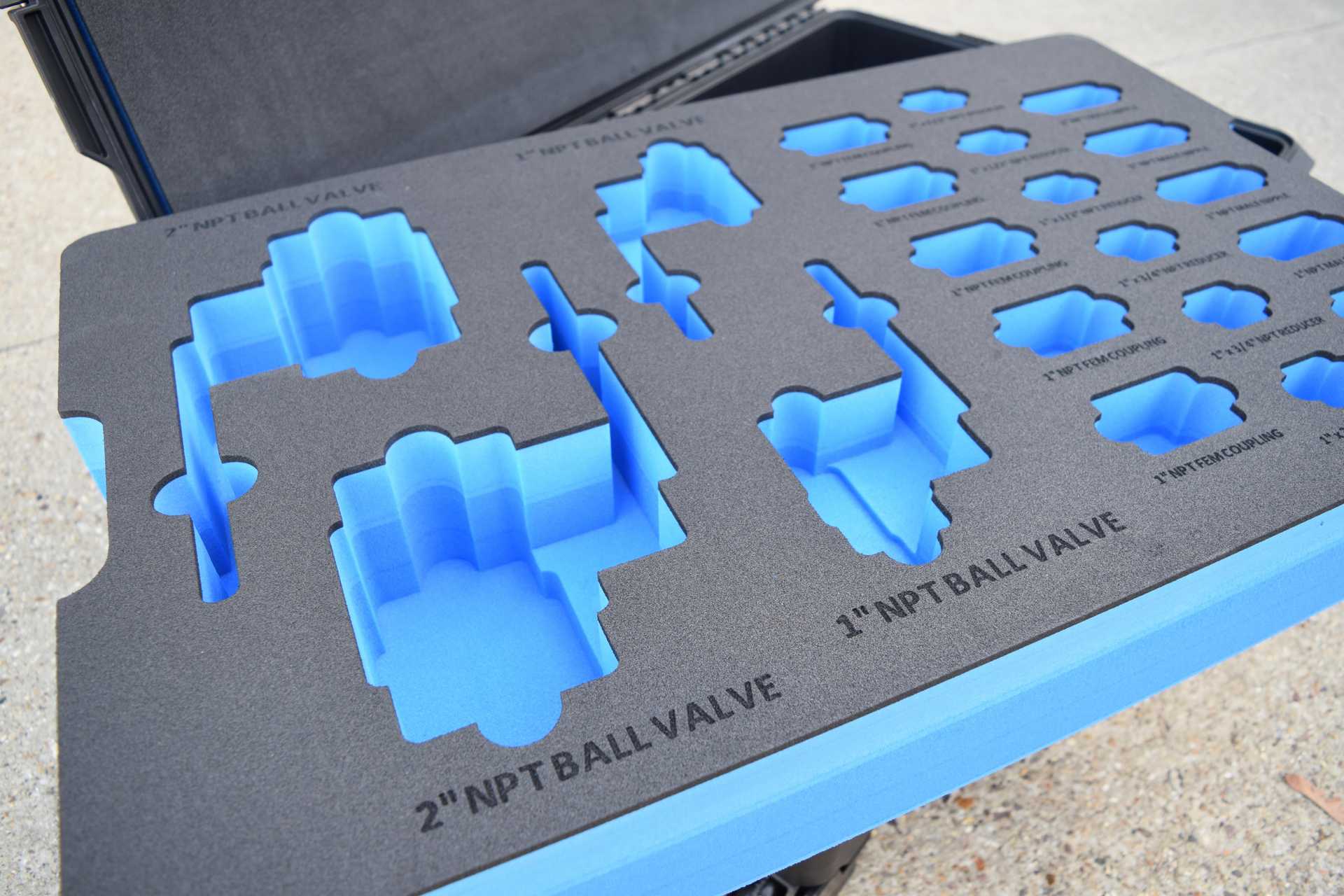

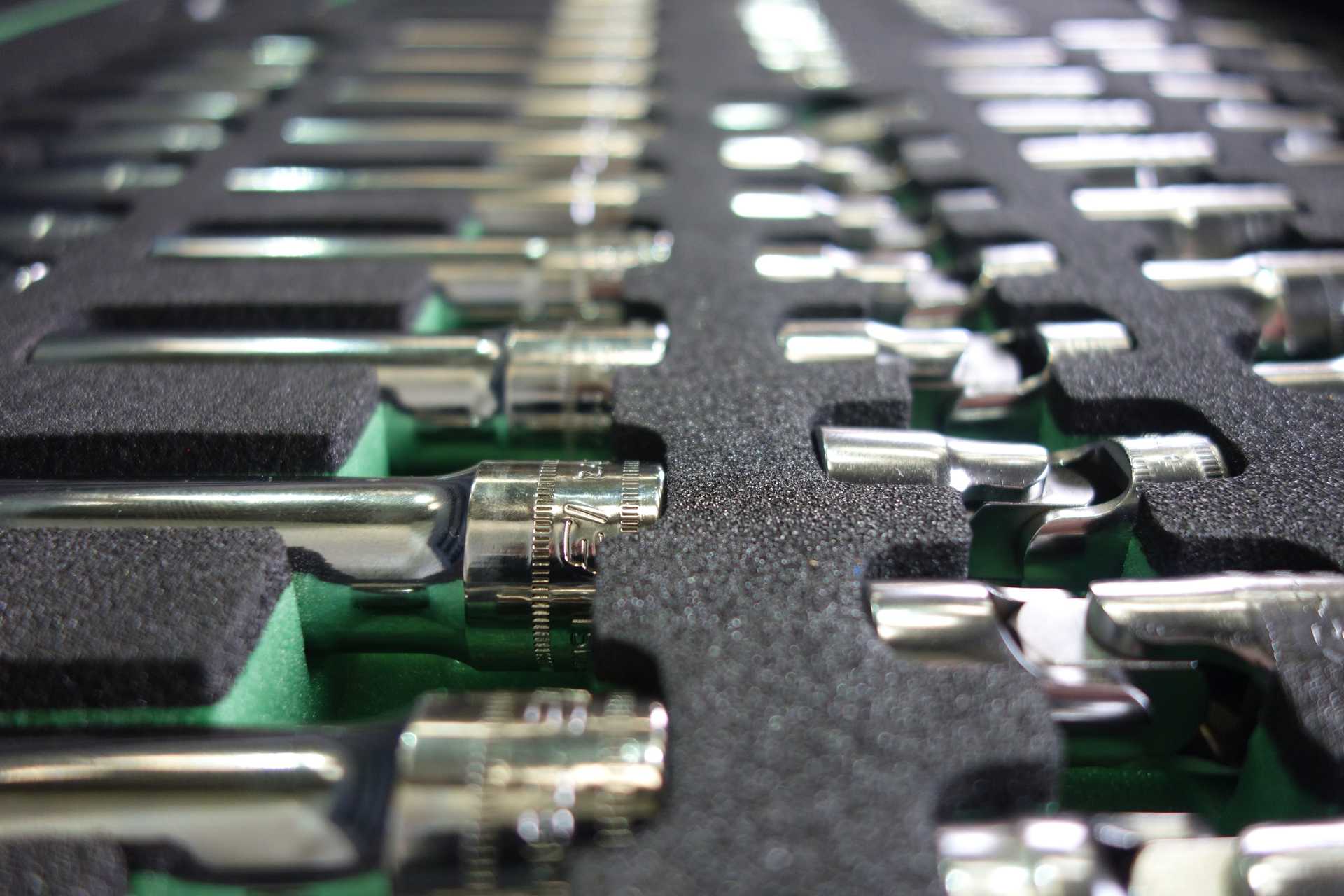

Good Policies Complimenting Your Tool ControlThis means that you should be taking measures to ensure that the practice of your business backs up your tool control. For example, the tools that are needed for a specific job should all be together in a toolkit. This should be done so that there are multiple toolkits for each maintenance job, ensuring that tools are in the right places. Before a job is signed off in the maintenance log, a tool control inspection should be completed. This should include checking that all the tools are there, that none of them are broken and so on. Don’t forget that broken tools can be just as problematic as missing tools, which is why all tools need to be inspected before and after use.

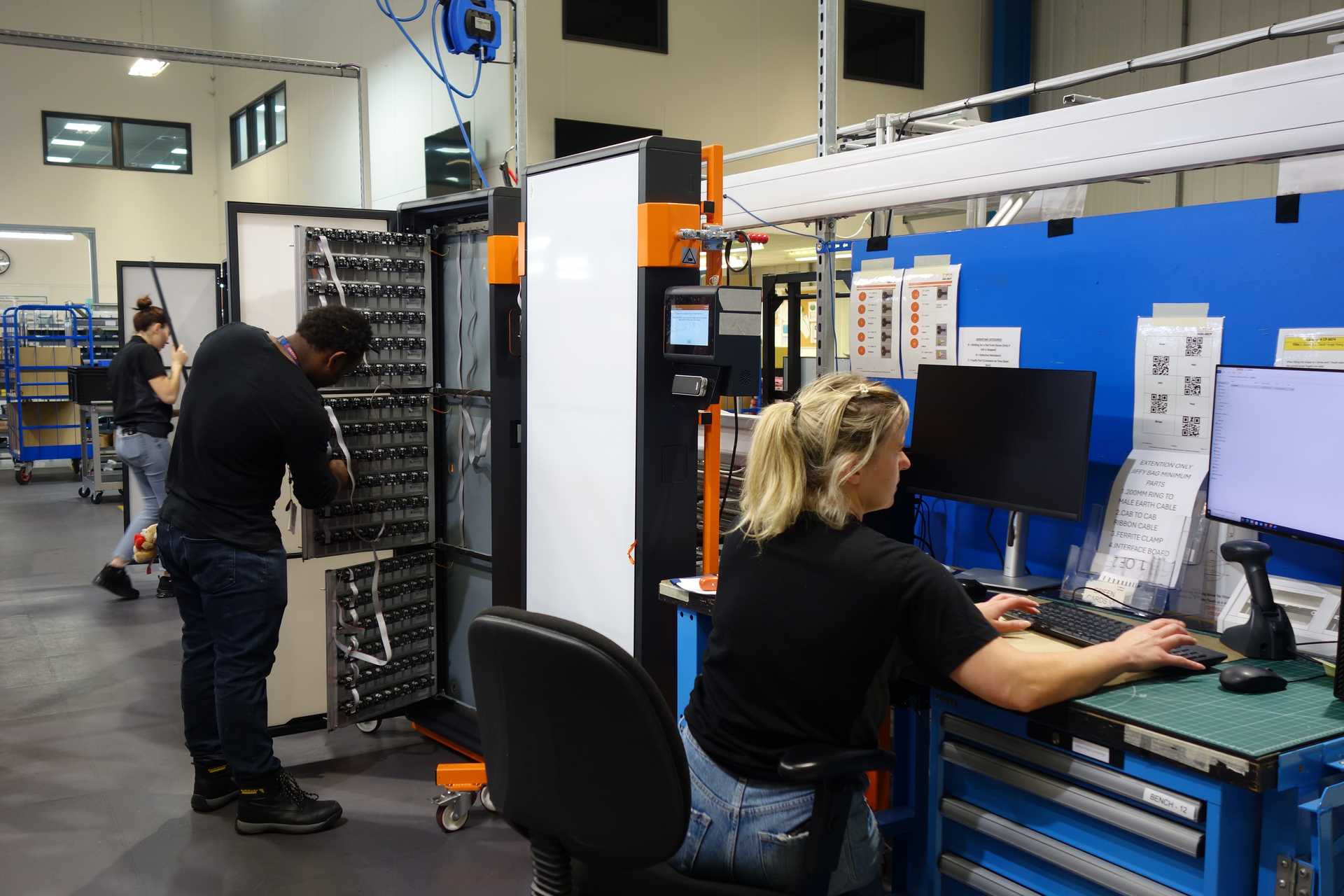

Tool Control Training In Induction ProgramsAll new starters to your business should be trained in tool control. As such, your induction programs should now include this in them to ensure that everyone understands what is expected of them when they start working for your company. Everyone needs to understand the standard operating procedures and the role that tool control plays in them. If they don’t, this is where things start to go wrong. If you offer training, nobody has the opportunity to turn around down the line and say they didn’t have the correct information to effectively manage tool control.

Remind Your Staff of Their ResponsibilitiesFinally, you should make sure that you are reminding your staff of their responsibilities when it comes to tool control. There are a few ways that you can do this, with the first being sending them on refresher courses every now and then. You should also think about hanging up posters in the workplace as a gentle reminder.

We hope that you have found this article helpful, and now see some of the best practice tips that you should be using when it comes to effective tool control. If you put these practices into place, then there should be no reason for tools to go missing anymore! We wish you the best of luck, and hope that you see results sooner rather than later!

Want to know more?

If you would like to discuss a project with us, we would be delighted to receive your call.

Call us today on 01908 307 956 or alternatively please contact us.