Blog

21 July 2022

The Role of Visual Tool Control in 5S Initiatives.

A 5S programme is often the starting point for a larger continuous improvement or efficiency programme. It is based on five steps: sort, set in order, shine, standardise and sustain.

Sort

Sort is based on the idea that space, time and energy can be saved by removing unnecessary clutter from workspaces. It requires all non-essential items to be removed from the workplace. Organising tools properly makes it easier to identify what is truly needed.

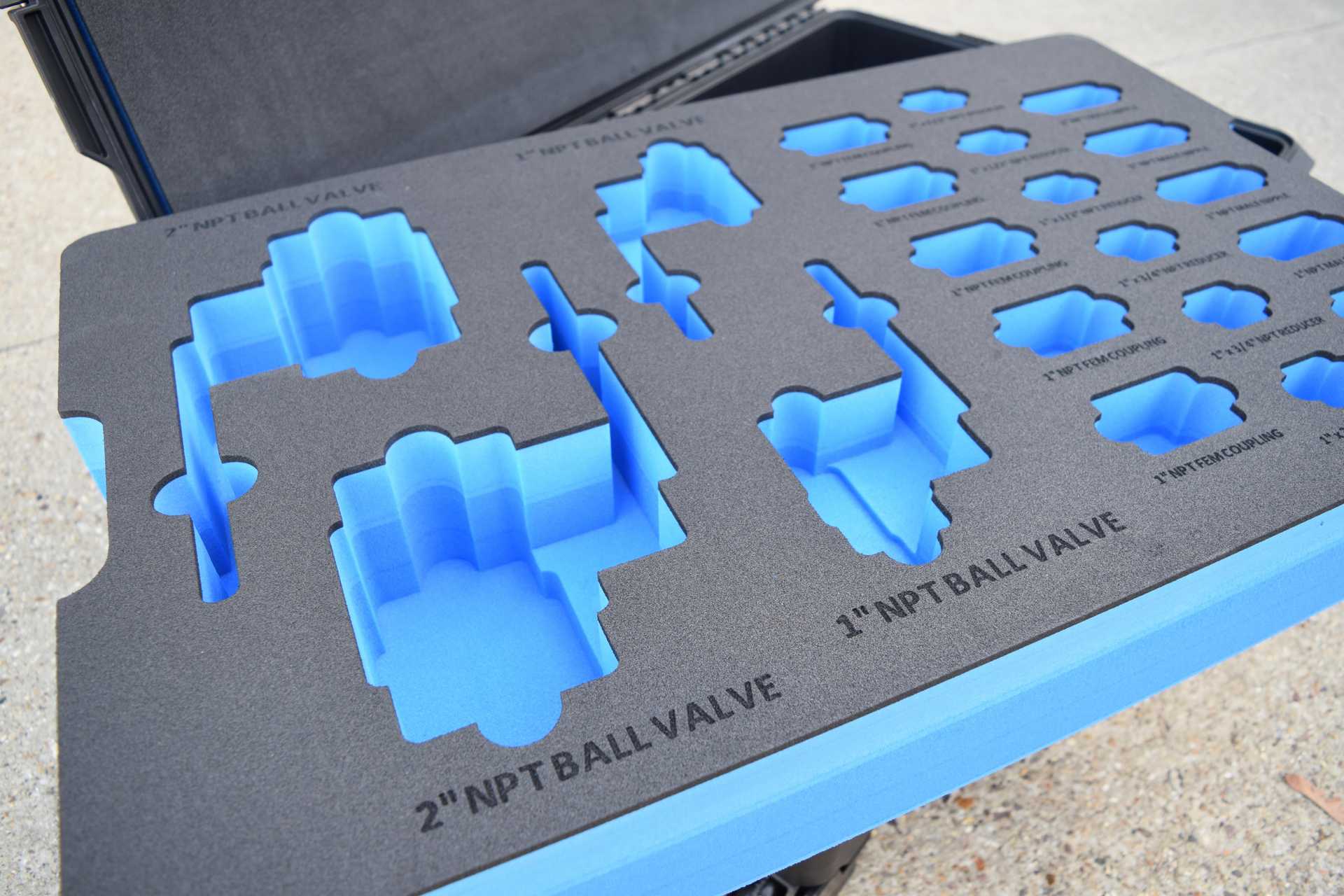

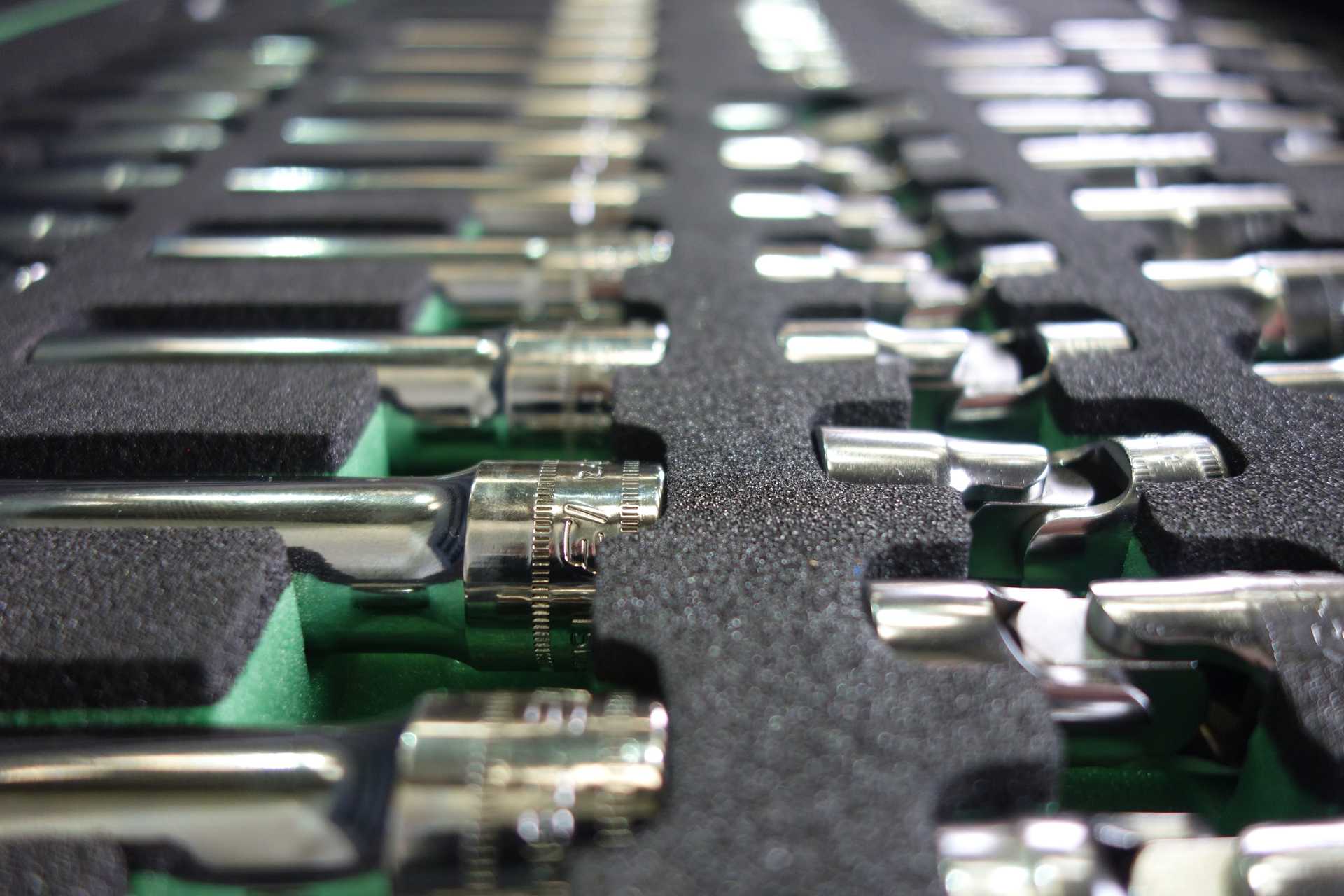

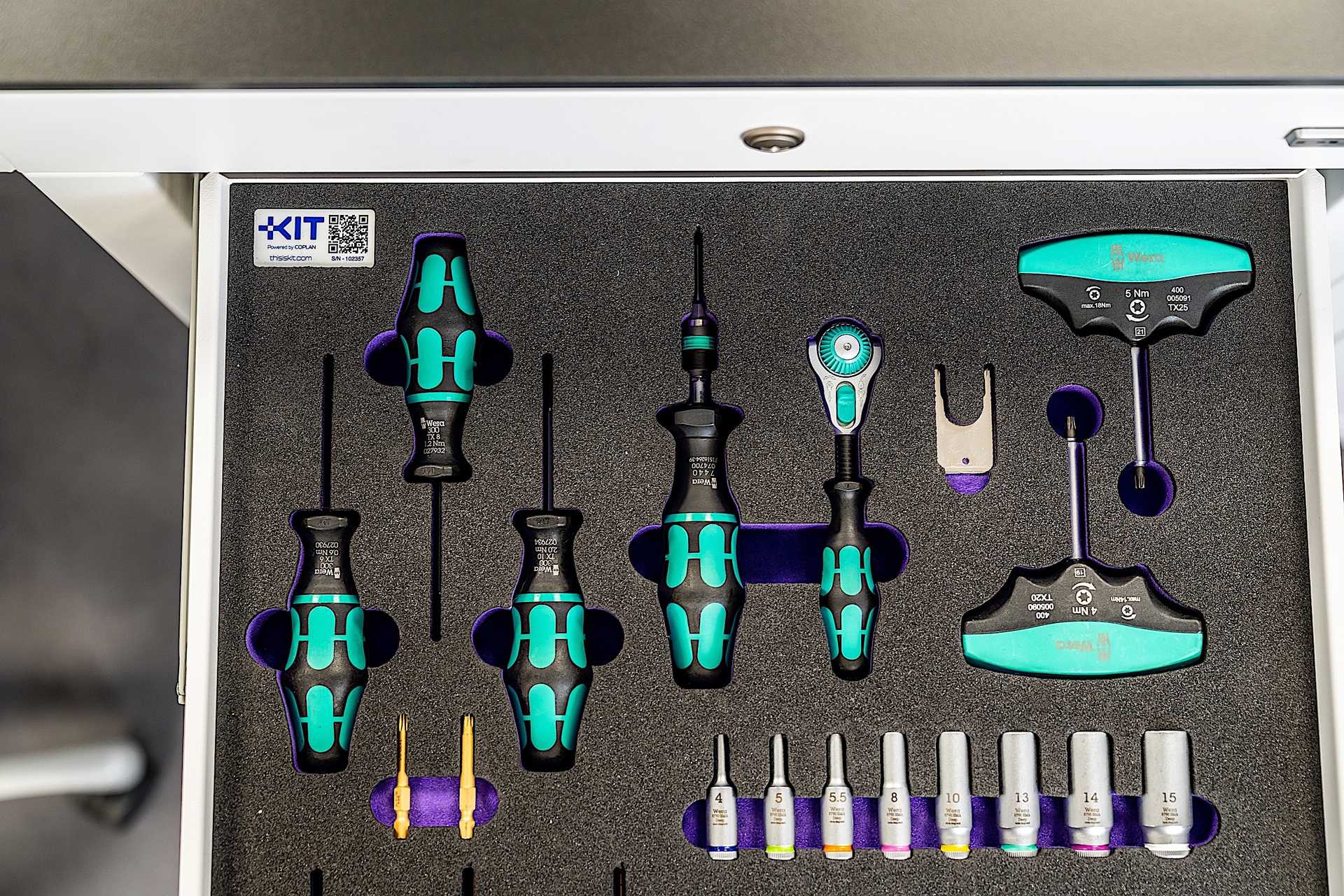

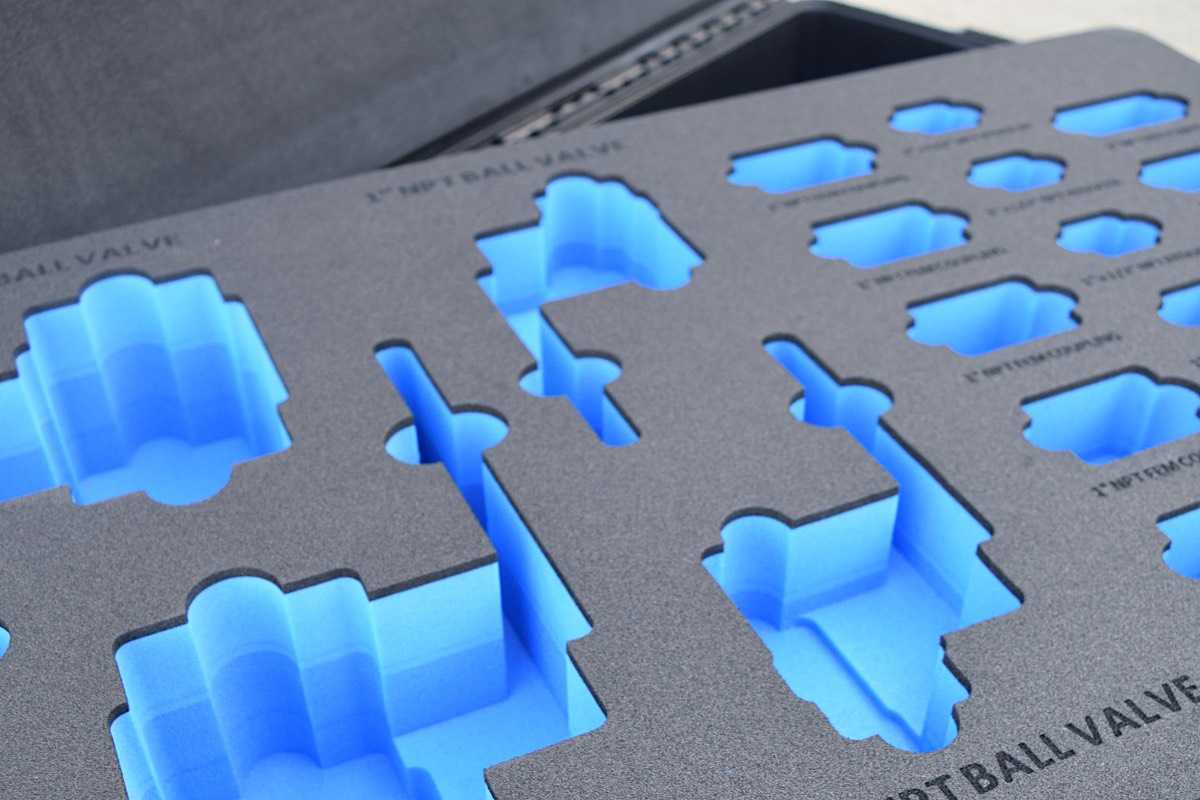

Set in orderTool control solutions have a clear role to play in the second 5S step: set in order. Set in order is based on the idea of a tidy workplace. Time wasted on unnecessary searching for or returning tools, materials or equipment should be avoided. Organisations need to make it easy for anyone and everyone to put tools away through clear labelling and a tidy workplace.

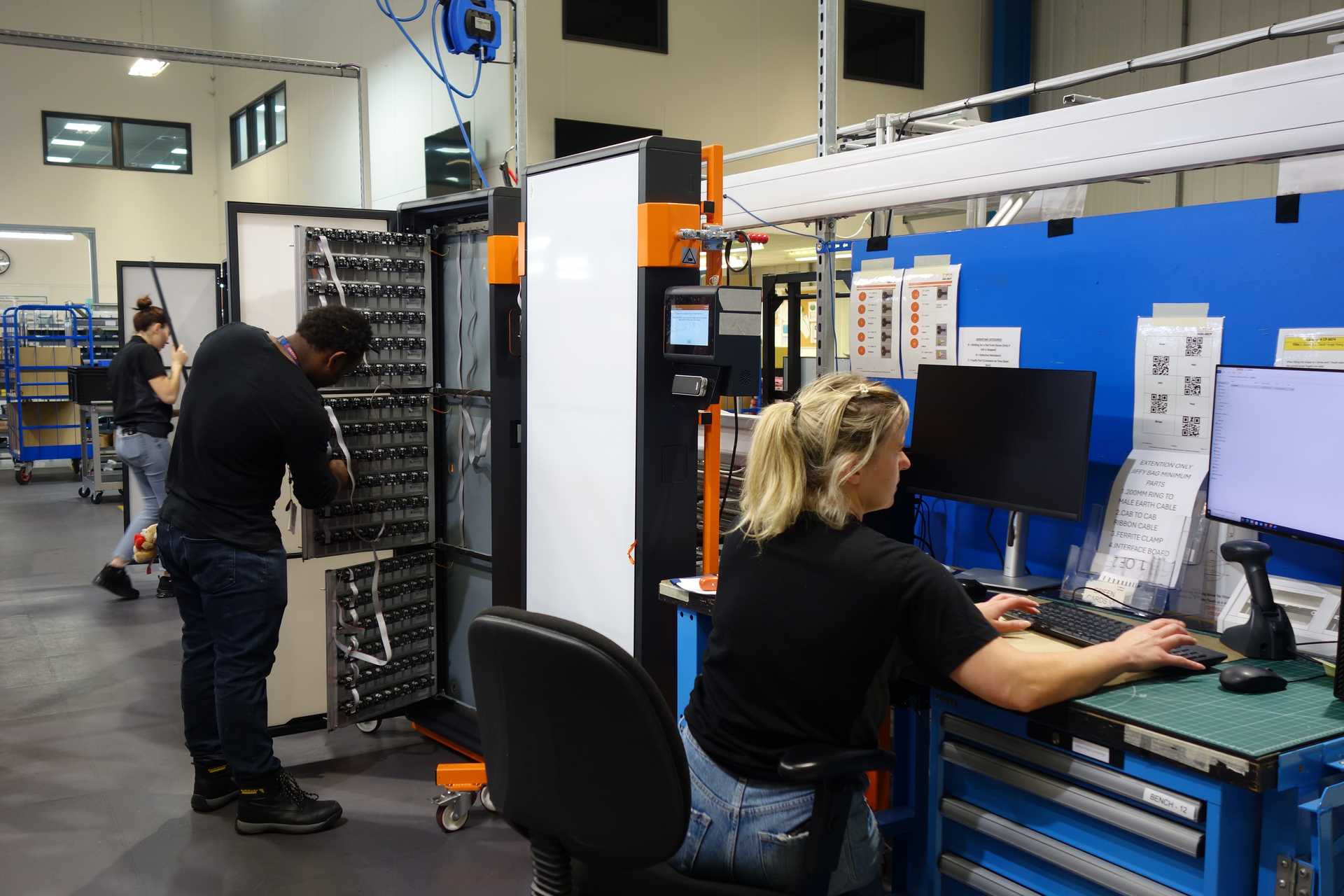

ShineShine is based on the idea that everyone has a responsibility for maintaining a clean and pleasant workspace. Clean, bright working spaces lead to improved morale, improved productivity and fewer absences. Tools should be inspected and cleaned before being replaced. Tool control makes for a tidy workplace. It also makes it easy to review the condition of tools.

StandardiseStandardise is based on the idea that best practices should be formalised and standardised. Visual communication, staff training and empowerment (encouraging staff to take responsibility for 5S initiatives) help to embed best practice.

SustainAs part of your 5S programme, tool control needs to be embedded within the organisational culture. Sustain is all about discipline and the need to practice the other 4S as a way of life. Continuing adherence to all steps helps to create the environment for continuous improvement. Revisit all steps within your 5S programme and, as part of this, review your tool control solutions and procedures on a regular basis to ensure maximum efficiency and continuous improvement. In conclusion, tool foam is highly beneficial when used to help achieve 5S initiative and to organise your tools throughout your company. If you are looking for a design, fabrication and support service that revolves around tool organisation, feel free to contact Coplan today.

Want to know more?

If you would like to discuss a project with us, we would be delighted to receive your call.

Call us today on 01908 307 956 or alternatively please contact us.